Founded in 1995, SKYTEX is a vertically integrated textile conglomerate and one of North America’s largest and most versatile manufacturing hubs. By consolidating all production stages—from extrusion, texturing, twisting, and yarn preparation to fabric dyeing and finished products—the company ensures rapid market responsiveness. SKYTEX holds extensive expertise in producing native and recycled polyester fibers, spandex, nylon, acetate, and viscose within the USMCA region, serving diverse markets including sportswear, fashion, home textiles, mattress fabrics, slats, carpets, and technical textiles through woven, knitted, jacquard, warp-knitted, and nonwoven technologies. Its industry leadership stems from uncompromising quality standards and unwavering commitment to excellence. Furthermore, SKYTEX prioritizes sustainability, actively contributing to global welfare through initiatives like zero-waste sustainability policies.

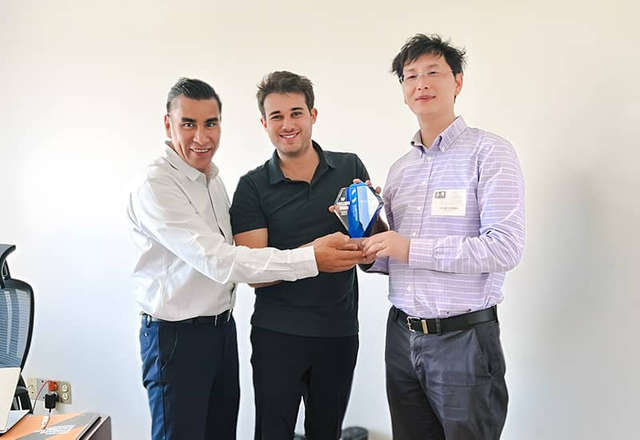

Since formalizing its partnership with SUNTECH in 2015, SKYTEX has deployed over 30 fabric inspection machines and warp beam handling equipment over the past decade. The consistent performance of these solutions has significantly optimized fabric quality control and enhanced loom beam transportation efficiency, demonstrating strong validation of SUNTECH’s technological capabilities and service reliability.