With the intelligent upgrading of the textile industry, AI fabric inspection machines have gradually become a popular choice in the market. However, traditional fabric inspection machines are still the main way to inspect fabrics for many companies. So, how big is the cost difference between AI fabric inspection machines and traditional fabric inspection machines? SUNTECH will make a detailed comparison from the aspects of purchase cost, labor cost, efficiency, false detection rate, maintenance cost, etc. to help make a more informed decision.

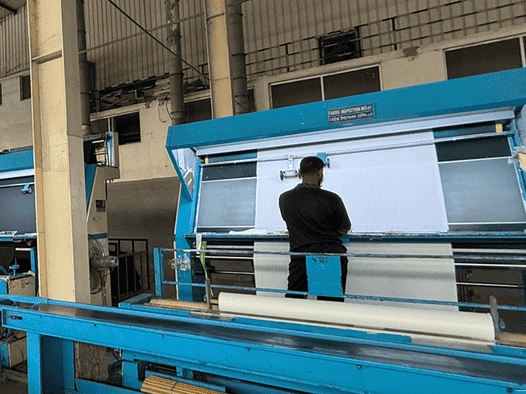

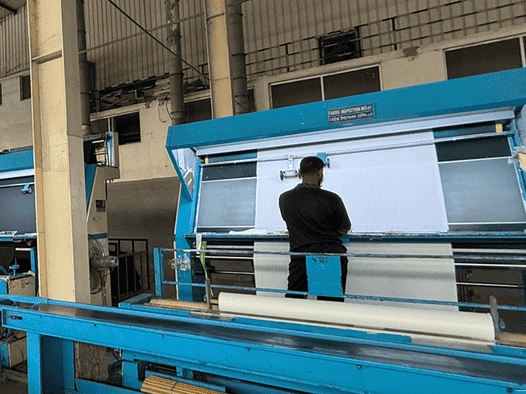

Cost Analysis of Classic Fabric Inspection Machines

Purchase Cost

The initial purchase cost of traditional fabric inspection machines is relatively low, depending on the machine model and function.

Labor Cost

Traditional fabric inspection machines need to rely on manual inspection of fabrics. Generally, at least 1-2 workers are required on a fabric inspection production line. This means that in the long run, labor costs will increase year by year with the increase in wages and social security.

Production Efficiency and Time Cost

The detection speed of traditional fabric inspection machines is slow, and manual operation also has fatigue problems, which may affect production progress. If long-term operation is required, shifts are also required, increasing costs.

False Detection Rate and Quality Loss Cost

Since manual inspection of fabrics is affected by subjective factors, the false detection rate is high, which may cause unqualified fabrics to enter the market, trigger customer complaints, and even require product recalls, increasing corporate losses.

Maintenance and Repair Costs

Traditional fabric inspection machines have many mechanical parts, which are prone to wear and tear after long-term use, and the maintenance frequency is high, and the maintenance cost is considerable.

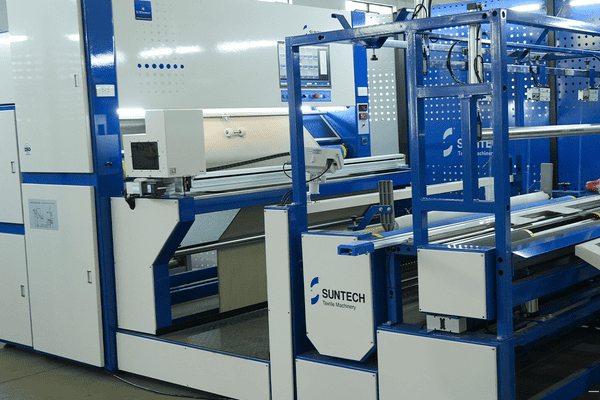

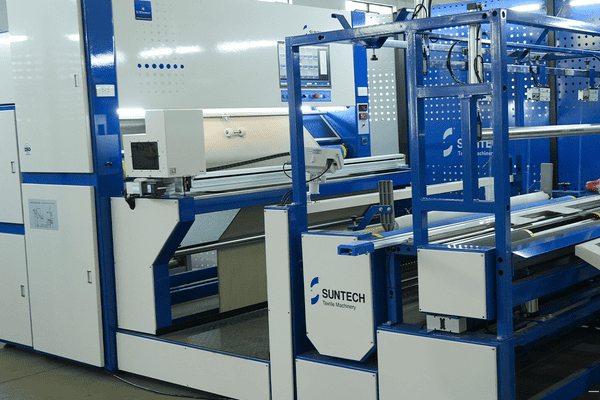

Cost Analysis of AI Fabric Inspection Machine

Equipment Purchase Cost

The initial purchase cost of an AI fabric inspection machine is high, mainly because it is equipped with a high-precision camera system, deep learning algorithm, and automatic control system.

Labor Cost

AI fabric inspection machines can realize fully automated fabric inspection, reducing the dependence on manual labor, and theoretically saving more than 80% of labor costs. One operator can manage multiple devices at the same time, greatly reducing long-term operating expenses.

Time Cost

The inspection speed of AI fabric inspection machine is 3-5 times faster than that of manual labor, and it can work 24 hours a day without shift change, which greatly improves production efficiency.

Rework Cost

The defect detection accuracy of AI fabric inspection machines can reach more than 85%, which is more stable than manual inspection, reducing the possibility of missed inspection and misjudgment and avoiding subsequent rework and quality complaints.

Maintenance Cost

Since AI fabric inspection machine uses more electronic components, mechanical wear is relatively less, fthe ailure rate is low, and maintenance cost is relatively low.

How to Choose a Fabric Inspection Machine?

Solutions for Factories of Different Sizes

Small factories: If the order volume is small and the budget is limited, traditional fabric inspection machines can still be selected, but long-term labor costs must be considered.

Medium and large factories: AI fabric inspection machines can significantly improve production efficiency and reduce costs, and are a more competitive choice in the long run.

Applicable Scenarios

AI fabric inspection machines are more suitable for companies that require high-quality and efficient testing, such as high-end textiles, functional fabrics, and other fields.

Balance of Cost and Benefit

If companies pursue long-term benefits and hope to reduce manual dependence and improve quality control, AI fabric inspection machines are a better choice.

Future Trends

With the development of intelligent manufacturing, the technology of AI fabric inspection machines will continue to be optimized and costs will gradually decrease. Although traditional fabric inspection machines still have a certain market, their limitations are becoming more and more obvious. In the future, AI fabric inspection machines will gradually replace traditional models.

Conclusion

Although the initial cost of AI fabric inspection machines is high, they have obvious advantages in labor costs, production efficiency, false detection rate, etc., and are more cost-effective in the long run. For textile companies, the choice of fabric inspection machine should be based on their own needs, budget, and development plan.