In today's textile industry, efficiency, safety, and sustainability are key driving forces behind the adoption of new technologies. Among these advancements, electric A-frame tractors have become increasingly popular. These tractors offer numerous advantages over traditional material-handling methods, transforming the way textile mills operate. But what makes them so beneficial? Let’s explore the various advantages of using electric A-Frame tractors in the textile industry.

What is an Electric A-Frame Tractor?

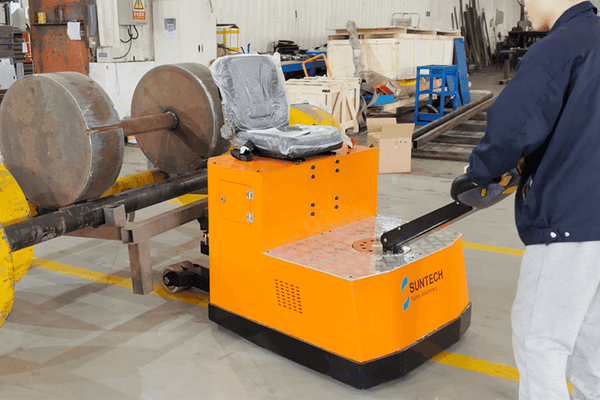

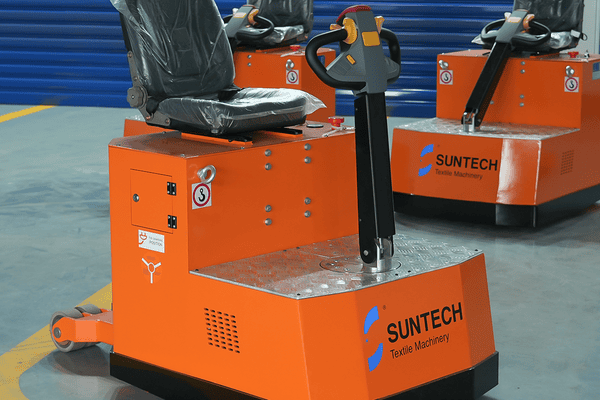

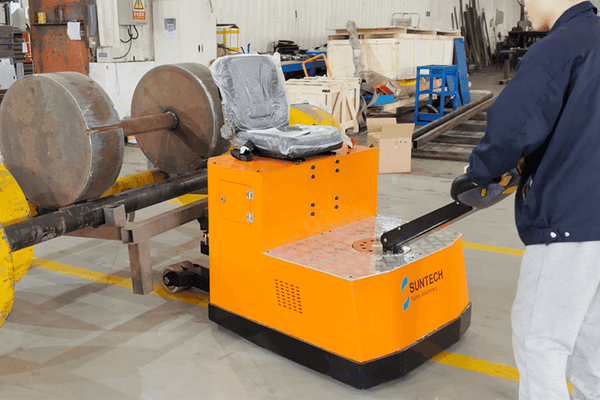

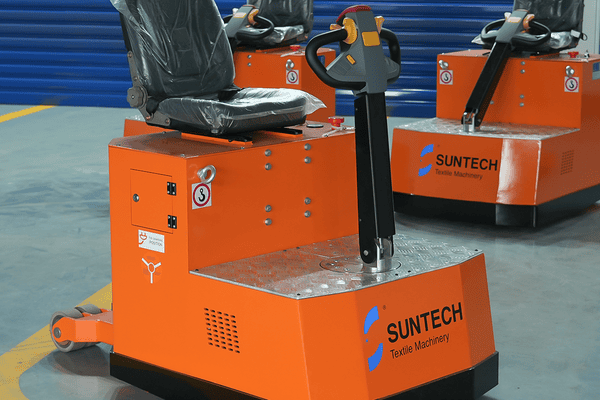

Before diving into the advantages, let’s first understand what an electric A-frame tractor is and how it works. An electric A-frame tractor is a type of motorized vehicle used to move materials within a textile factory. Unlike traditional tractors that rely on internal combustion engines, these tractors are powered by electricity, making them more efficient and environmentally friendly. They feature a unique A-frame design that enables them to carry large, heavy loads in a compact, maneuverable manner, often used for transporting raw materials, finished products, or even heavy equipment across factory floors.

Traditional Methods in the Textile Industry

Traditionally, textile manufacturers relied on manual labor, forklifts, and other large machinery to move materials within their facilities. While these methods worked, they often came with several limitations, such as:

Labor Intensity: These methods require significant human intervention, leading to higher labor costs and a greater risk of worker fatigue and injury.

Space Constraints: Larger machinery, such as forklifts, often struggled to navigate smaller spaces or congested areas of the factory.

Environmental Impact: Traditional equipment often runs on fossil fuels, contributing to a larger carbon footprint and higher emissions.

Advantages of Using Electric A-Frame Tractors

1. Efficiency and Speed in Material Handling

Electric A-frame tractors are designed for high-speed operation. Unlike traditional methods, these tractors can quickly transport materials from one location to another, significantly improving the overall workflow. With electric motors providing instant torque, these tractors can handle heavy loads without compromising speed. This efficiency results in less downtime and faster production cycles.

2. Reduction in Labor Costs

Since electric A-frame tractors are automated and easy to operate, they reduce the need for manual labor in the material-handling process. This not only lowers labor costs but also minimizes human error, leading to smoother operations and fewer mistakes. Operators can focus on more value-added tasks rather than constantly moving materials by hand.

3. Eco-friendly and Energy-efficient

Electric A-frame tractors are a green alternative to traditional fuel-powered machinery. Powered by rechargeable batteries, these tractors produce zero emissions during operation, making them far more environmentally friendly. The energy efficiency of electric motors also means lower energy consumption, reducing both operational costs and the facility’s carbon footprint.

4. Increased Safety and Reduced Manual Errors

One of the most significant advantages of electric A-frame tractors is their ability to enhance workplace safety. With automated features and reduced human intervention, the risk of accidents and injuries is minimized. Moreover, these tractors often come equipped with safety sensors, such as obstacle detection and automatic braking systems, which prevent potential collisions and improve overall safety.

How Electric A-Frame Tractors Improve Workflow

Electric A-frame tractors are not only faster but also more versatile than traditional material handling equipment. They can easily navigate through tight spaces and narrow aisles, a common feature in textile manufacturing environments where space optimization is crucial. Their ability to work in close quarters ensures that every inch of the factory floor is used efficiently.

Enhanced Load Capacity and Versatility

Electric A-frame tractors can carry substantial loads with ease. Their ability to haul heavy materials without any noticeable strain allows for more effective material handling and reduces the need for multiple trips. The added versatility makes them suitable for a wide range of tasks, from moving finished textiles to carrying raw materials across large production areas.

Easy Maneuverability in Limited Spaces

In textile factories where space can be limited, maneuverability is key. Electric A-frame tractors excel in this area, thanks to their compact size and intuitive steering systems. They can easily navigate crowded factory floors, delivering materials to the right place with precision and without the need for additional operators.

Cost-Effectiveness of Electric A-Frame Tractors

While the initial investment in electric A-frame tractors may seem higher compared to traditional methods, the long-term cost savings far outweigh the initial expenditure.

Long-Term Savings on Labor

As mentioned earlier, electric A-frame tractors reduce the need for manual labor, leading to substantial savings over time. Fewer workers are needed to operate these machines, and the risk of injury-related costs is significantly reduced. Additionally, automation improves overall productivity, which in turn contributes to greater output and profitability.

Reduced Operational and Maintenance Costs

Electric tractors are not only cheaper to run but also require less maintenance compared to their fuel-powered counterparts. With fewer moving parts and no need for regular oil changes or exhaust systems, maintenance costs are kept to a minimum. Over time, this leads to substantial savings for textile manufacturers.

Safety Benefits of Electric A-Frame Tractors

Safety is paramount in any industrial environment, and electric A-frame tractors provide a higher level of safety compared to traditional methods.

Minimization of Workplace Accidents

Automated electric tractors reduce human error, one of the leading causes of workplace accidents. The smart sensors on these tractors detect obstacles, prevent collisions, and help operators avoid potential hazards. The result is a safer working environment for all employees.

Smart Safety Features and Automation

Electric A-frame tractors often come with advanced safety features, such as automatic speed control, collision avoidance, and emergency stop systems. These features not only protect workers but also enhance the overall efficiency of the production process.

Impact on Textile Industry’s Sustainability

The textile industry is increasingly focusing on sustainability, and electric A-frame tractors play a pivotal role in this shift. By reducing emissions and energy consumption, these tractors contribute to a greener, more sustainable manufacturing process.

Ease of Maintenance

Compared to traditional machinery, electric A-frame tractors require far less maintenance. Their advanced diagnostics systems allow for early detection of potential issues, and remote monitoring ensures that any problems are addressed quickly before they lead to downtime.

Conclusion

In conclusion, the advantages of electric A-frame tractors in the textile industry are clear. From enhanced efficiency and safety to reduced environmental impact, these machines offer a host of benefits that make them an invaluable asset for modern textile manufacturers. As the industry continues to evolve, the widespread adoption of electric A-frame tractors will play a key role in shaping the future of textile production.