In the dynamic world of textiles, efficient storage systems are vital for ensuring smooth operations, optimizing space utilization, and safeguarding valuable textile rolls. Choosing the ideal beam storage system for your textile business involves careful consideration of several factors. In this blog post, we will provide you with a comprehensive guide on selecting the best beam storage system.

Assess Your Space and Layout

Start by evaluating the available space in your facility and the layout of your textile production area. Take into account the dimensions and height of the storage area, as well as any specific requirements for aisles and access points. Understanding these aspects will enable you to determine the optimal size and configuration of the beam storage system.

Determine the Beam Type

Next, consider the various types of beams used in storage systems, such as box beams, I-beams, and channel beams. Each beam type possesses its own load-bearing capacity, durability, and compatibility with specific textile products. Evaluate the weight and dimensions of your textile rolls to ensure that the chosen beams can effectively handle the load.

Evaluate Storage Density

Assess your storage needs in terms of volume and density. Determine the number of textile rolls you need to store and the frequency of access. If you have a large volume of rolls and limited access requirements, high-density storage systems like drive-in racks or push-back racks might be suitable. Conversely, if you require easy access to individual rolls, selective racks would be more appropriate.

Prioritize Safety and Accessibility

When it comes to storage systems, prioritizing safety is of utmost importance. Look for beam storage systems that comply with safety standards and incorporate features like load stops, safety pins, and secure locking mechanisms. Additionally, ensure that the chosen system allows for easy loading and unloading of textile rolls, reducing the risk of accidents or damage.

Plan for Scalability and Flexibility

Anticipate the future growth and evolving needs of your textile business. Opt for a beam storage system that offers flexibility and scalability, enabling effortless expansion or reconfiguration as your storage requirements change. This flexibility empowers you to adapt to market demands without significant disruptions or the need for substantial additional investments.

Budget Considerations

Evaluate the overall cost of the beam storage system, including installation, maintenance, and any necessary accessories. While it is crucial to consider your budget, strike a balance between the initial investment and the long-term benefits and efficiency gains. Investing in a high-quality storage system can lead to substantial cost savings and operational improvements over time.

Choose a Reputable Supplier

Lastly, choose a supplier or manufacturer with a solid reputation and experience in the textile industry. Conduct thorough research, read customer reviews, and check references to assess the quality of their products and customer service. A trusted supplier will offer guidance and support throughout the selection and installation process, ensuring a seamless and successful implementation.

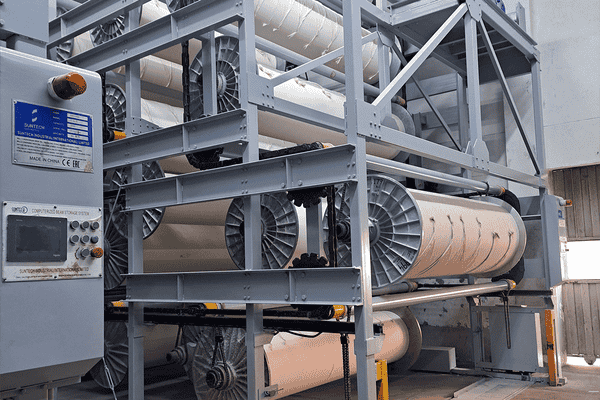

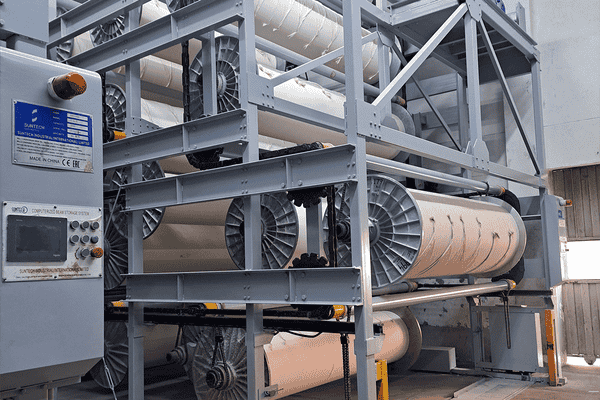

SUNTECH Beam Storage system, with its advantages of "small space, large capacity, low cost, and high intelligence," solves the warehousing challenges for textile enterprises and has received unanimous praise from the industry.

Beam Storage is the optimal choice for storing spindles, beams, loom beams, and fabric rolls, and is widely used in pre-weaving preparation, weaving factories, and dyeing and finishing factories. It is an ideal equipment for textile factories to effectively utilize space, reduce floor space, increase storage capacity, achieve efficient storage and retrieval, and realize modern intelligent management. It is similar to a large shelf or a three-dimensional intelligent garage, creating large capacity in a small space, providing convenience for mechanical scheduling with intelligent mode, maximizing floor space savings, and significantly reducing warehousing costs.

SUNTECH Textile Machinery is a well-known and long-established textile machinery company that is renowned for its technological innovations. It started with textile and warehousing machinery, and has a wide range of textile machinery equipment involved in finished fabric warehousing, handling, inspection, packaging, and other processes. Among them, Beam Storage is a classic product that has won multiple awards and has applied for multiple patented technologies such as Beam Storage system operation software and chain synchronization detection, and is highly favored by international textile enterprises.

Conclusion

Selecting the best beam storage system for the textile industry involves a thorough evaluation of space, beam type, storage density, handling equipment, safety, scalability, budget, and supplier reputation. By considering these factors and making informed decisions, you can optimize space utilization, enhance operational efficiency, and protect your valuable textile rolls. Invest time in the selection process to ensure that your chosen beam storage system aligns with your business goals and sets the foundation for future growth.