The fabric relaxing machine is an indispensable piece of equipment in the textile production line. Its main function is to release the tension of the fabric to prepare for subsequent dyeing, finishing, processing, and other subsequent processes. In large-scale production, the performance of the fabric relaxing machine is particularly important because it directly affects production efficiency, fabric quality, and the stability of the final product.

In large-scale production, fabric tension management and uniformity control are crucial. Without a suitable fabric relaxing machine, the fabric is prone to deformation, shrinkage, or stretching during the production process, which in turn affects the final quality of the product. Therefore, textile mills must choose an efficient and reliable fabric relaxing machine

Fabric Relaxing Machine Introduction

Function of Fabric Relaxing Machine

Fabric Relaxing Machine releases fabric tension through a variety of processes, including vibration relaxation, air flow relaxation and mechanical relaxation. They gradually release fabric tension to the minimum through different technical means, thereby ensuring fabric stability during subsequent processing.

Operation of Fabric Relaxing Machine

The core components of the fabric relaxing machine include conveyor belt, fabric relaxing roller, pressure device, adjustment system, etc. Each component affects the fabric relaxing effect to varying degrees. A good fabric relaxing machine can accurately adjust these components to ensure the best relaxing effect.

Considerations When Choosing a Fabric Relaxing Machine for Large-Scale Production

Production Scale and Fabric Relaxing Machine Selection

When choosing a fabric relaxing machine, production scale is an important consideration. For large-scale production, equipment with high capacity and stability must be selected. Otherwise, the equipment may not be able to cope with high-load production tasks, resulting in downtime or equipment damage.

Equipment Stability and Maintenance Requirements

Equipment stability is an important condition for ensuring uninterrupted production. High-quality fabric relaxing machines usually has an automated monitoring system that can monitor the equipment status in real time and warn of potential failures in advance, thereby reducing downtime.

Matching Fabric Type with Fabric Relaxing Process

Different types of fabrics require different fabric relaxing processes. For example, highly elastic fabrics may require special loosening processes to avoid deformation of the fabric. For natural fiber fabrics, traditional mechanical fabric relaxing processes may be more suitable. Therefore, when choosing a suitable fabric relaxing machine, the type and characteristics of the fabrics used in production must be taken into account.

Energy Saving and Environmental Protection Performance

With the improvement of environmental protection requirements, many manufacturers have begun to pay attention to the energy-saving performance of equipment when selecting equipment. An efficient fabric relaxing machine should have good energy efficiency, which can reduce energy consumption and production costs while ensuring the loosening effect.

Recommend SUNTECH Fabric Relaxing Machine

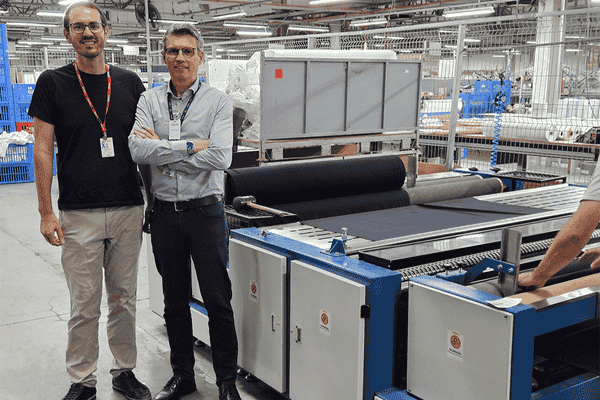

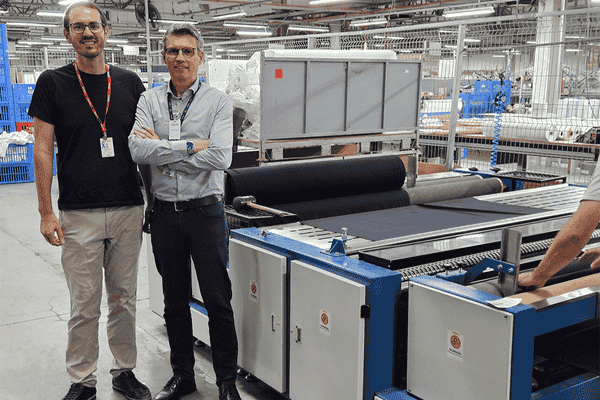

As a leading textile machinery manufacturer in the industry, SUNTECH's fabric relaxing machine is widely used in large-scale production due to its excellent performance and stability. SUNTECH's fabric relaxing machine adopts an advanced triple relaxing process, which can release the tension of the fabric to the greatest extent. The equipment has a compact structure and is suitable for production lines of different sizes.

How to Maintain Fabric Relaxing Machine

Regular Inspection and Maintenance

Check the fabric relaxing machine regularly to ensure that all parts are operating normally. In particular, parts such as fabric relaxing rollers and conveyor belts are prone to wear and tear and need to be replaced or repaired in time.

Importance of Cleaning Work

Clean the fabric relaxing machine regularly to prevent dust, fiber residues, and other impurities from affecting the performance of the equipment. Keeping the equipment clean can not only extend the life of the equipment but also improve production efficiency.

Application of Automated Detection System

Modern fabric relaxing machines are usually equipped with automated detection systems that can monitor the operating status of the equipment in real time and issue early warnings when problems are found. This system can help operators detect equipment failures in time and reduce downtime.

Development Trend of Fabric Relaxing Machines

Combination of Intelligence and Automation

With the development of Industry 4.0, more and more fabric relaxing machines are beginning to incorporate intelligent technology. Through big data analysis, the equipment can automatically optimize the fabric relaxing parameters, improve production efficiency, and reduce human intervention.

Green and Environmentally Friendly Production Concept

Environmental protection has become a trend in global textile production. Future fabric relaxing machines will pay more attention to the control of energy consumption and waste emissions. By using more environmentally friendly materials and processes, the production process of fabric relaxing machines will be greener and lower-carbon.

Multifunctional Integrated Equipment

SUNTECH's fabric relaxing machine is not limited to the fabric relaxing function, but may also integrate more functions, such as automatic cutting, automatic measurement of fabric width, etc., to further improve production efficiency.

Conclusion

The cloth loosening machine suitable for large-scale production must not only have a strong fabric relaxing ability, but also meet multiple requirements such as high efficiency, stability, and energy saving. Choosing a suitable fabric relaxing machine can significantly improve production efficiency and reduce losses in production. With the development of technology, SUNTECH's fabric relaxing machine will be more intelligent and environmentally friendly, bringing greater innovation and progress to the textile industry.