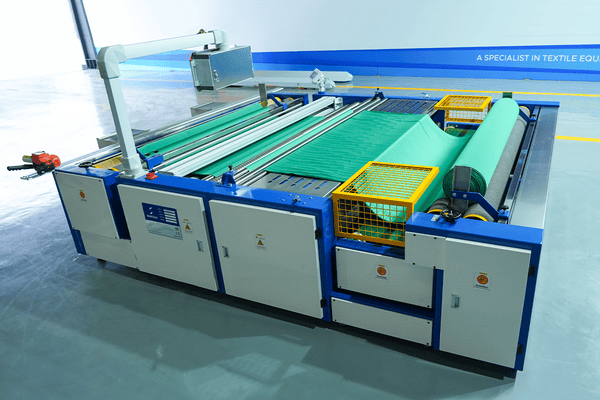

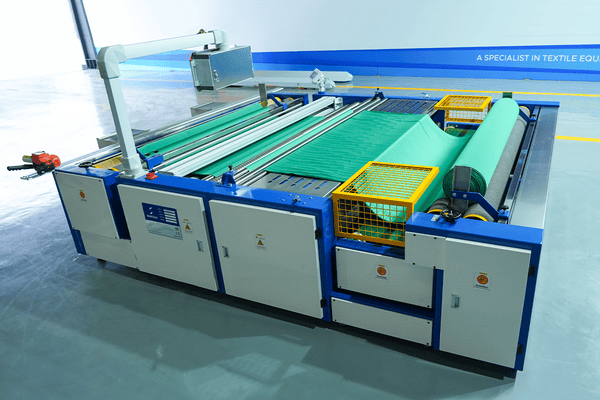

During the textile production process, fabrics usually have high tension after weaving, dyeing and finishing. If not properly relaxed, the fabric may have unstable dimensions, stiff feel, and difficulty in subsequent processing. SUNTECH roll-to-roll fabric relaxing technology, as an efficient continuous processing solution, is becoming an important choice for mass textile manufacturers.

What is Roll-to-Poll Fabric Relaxing?

Roll-to-roll fabric relaxation is an automated, continuous fabric treatment method that aims to release the internal tension of the fabric, restore it to its natural state, and improve its dimensional stability and feel. In this process, the fabric is slowly unfolded under controllable tension through special equipment and relaxed by steam or heat treatment technology to reduce the internal stress of the fabric.

Compared with the traditional batch relaxation method, roll-to-roll fabric relaxation does not require stopping for batch change and can continuously process large batches of fabrics, improving production efficiency while ensuring more uniform fabric quality.

Importance of Fabric Relaxing

Fabrics are affected by various external forces during the production process, such as mechanical stretching, temperature and humidity changes, etc., which lead to the accumulation of internal tension in the fibers. If effective relaxation treatment is not carried out, the final product may shrink and deform after washing, affecting the wearing experience and durability of the clothing.

Roll-to-roll fabric relaxing can effectively optimize the dimensional stability of the fabric, reduce shrinkage problems, and improve the feel of the fabric, making it softer and smoother. In addition, the relaxed fabric is easier to carry out subsequent processing, such as printing, dyeing, coating, or cutting, thereby improving overall production efficiency.

Traditional fabric relaxation method vs. roll-to-roll fabric relaxation

Traditional fabric relaxation methods mostly use batch processing, that is, spreading the fabric and letting it slowly restore tension under natural static or high-temperature steam. However, this method has many problems, such as long processing time, low efficiency, uneven fabric relaxation, etc.; especially for large-scale production, it is difficult to meet the needs of the modern textile industry.

In contrast, roll-to-roll fabric relaxation uses fully automated equipment for continuous processing, which greatly improves production efficiency. In addition, this technology ensures that the fabric remains evenly relaxed during processing through an intelligent tension control system to avoid local overstretching or insufficient relaxation.

Core Technologies

The efficiency and stability of roll-to-roll fabric relaxation mainly rely on the following key technologies:

-Intelligent tension control system: The equipment can automatically sense the tension of the fabric and adjust the transmission speed to prevent over-stretching or insufficient relaxation.

-Temperature and humidity adjustment technology: Through the steam or hot air system, the temperature and humidity environment of the fabric is adjusted to make it easier to relax and improve the final feel and quality.

-Automatic deviation correction system: During the fabric transmission process, the equipment will automatically detect and correct the position of the fabric to prevent deviation or wrinkles.

-High-speed continuous operation: It can continuously process large quantities of fabrics and greatly improve production efficiency.

These advanced technologies enable roll-to-roll fabric relaxation equipment to meet the production needs of high efficiency, stability, and automation.

What Textiles are Suitable For?

Roll-to-roll fabric relaxation is suitable for various textile types, especially fabrics with high requirements for dimensional stability. For example:

Knitted fabrics (T-shirt fabrics, sportswear fabrics)

Woven fabrics (shirt fabrics, denim)

Stretch fabrics (yoga clothes, swimwear fabrics)

Functional fabrics (waterproof and breathable fabrics, composite fabrics)

For dyeing and finishing plants, garment factories, and home textile companies, roll-to-roll fabric relaxation technology is an important choice for improving product quality and optimizing production processes.

Five Benefits of Using Roll-to-Roll Fabric Relaxing

1. Improve production efficiency: Due to the continuous processing mode, there is no need for frequent shutdowns, and the overall production efficiency is higher.

2. Optimize fabric quality: The intelligent tension control system ensures uniform fabric relaxation, reduces defects, and improves dimensional stability.

3. Save labor costs: The high degree of automation reduces the need for manual intervention and reduces labor costs.

4. Reduce energy consumption and loss: The equipment is optimized to effectively reduce steam and energy consumption while reducing the fabric loss rate.

5. Wide range of applications: It can be used for various types of textiles, with strong adaptability to meet different production needs.

How to Choose the Right Fabric Relaxing Machine?

When choosing roll-to-roll fabric relaxing equipment, companies need to consider the following aspects:

-Fabric type: Different equipment is suitable for different types of fabrics. For example, high-elastic fabrics require a more precise tension control system.

-Production scale: Choose the appropriate equipment model according to the factory's production volume to ensure capacity matching.

-Automation degree: Highly automated equipment can reduce manual operations, improve efficiency, and reduce human errors.

-Energy consumption and maintenance: High-quality equipment usually has the characteristics of low energy consumption and easy maintenance, which can reduce long-term operating costs.

-After-sales service: Choosing a supplier with good after-sales support can ensure the long-term stable operation of the equipment and obtain timely technical support.

Conclusion:

The roll-to-roll fabric relaxing machine has become an ideal choice for modern textile companies due to its high efficiency, stability and low cost. As the industry's demand for automation and intelligence increases, this technology will play a greater role in the future and help companies improve their competitiveness.

For companies that want to optimize production processes and improve product quality, now is the best time to introduce roll-to-roll fabric relaxing technology.