How to reduce the labor costs, how to improve intelligent operations and make automatic and intelligent operations more and more to replace the manual work in the handling process? It has become an important issue that warehousing and logistics people have to face. SUNTECH's Electric Warp Beam Lift Trolley with AGV technology Is the ideal solution for textile industry at present, that is, to realize the intelligent and automation of the material handling.

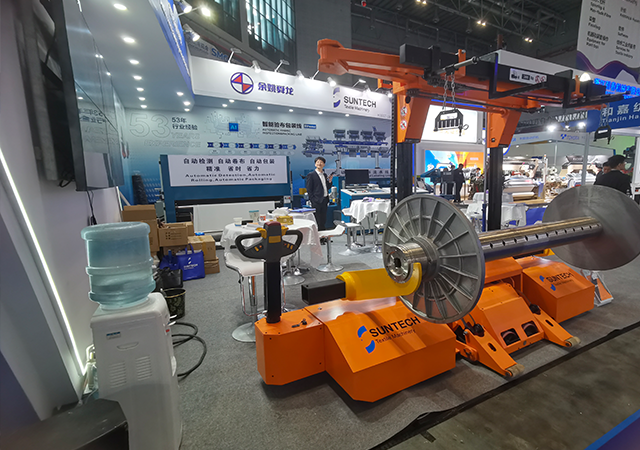

ST-MBT-02I SUNTECH Electric Warp Beam Lift Trolley

ST-MBT-02I is the newest model which is suitable for bottom beam transporting, inserting in weaving machines, weaving beam weighing up to 1800kg and beam width as per requirement, additional loading capacity of 300kg for harness.

The trolley is applicable for any weaving machines with their normal working width 170-340cm without changing its size.

The harness is accommodated by the standard take-up for harness frame and the contact rails and dividing rails or the complete warp stop motion.

Most enterprises still retain the human habit due to its infancy digital and intelligent transformation of most enterprises, and the advantages of AGV are not fully recognized, also the industry education is obviously insufficient.

In the domestic market in the past few years, the price of labor is far lower than the cost of technological reform. AGVs without efficiency advantages are not enough to solve logistics pain points, so AGVs have never been able to enter the popularization level.

In fact, many companies in warehousing and logistic industry have always had the problem of labor shortage or difficulty in labor, which is even more obvious under the influence of the epidemic catalyst. Therefore, the epidemic is a development opportunity for the AGV industry, or the opportunity outweighs the challenge, which is conducive to the promotion of the AGV industry.

Compared with manpower and traditional forklift equipment, the unique advantage of AGV equipment is mainly in flexibility.

Types of AGV Beam Transport Trolley

1. According to the navigation method: direct coordinate navigation method, electromagnetic navigation method, magnetic navigation method, laser navigation method, optical navigation method, inertial navigation method, image recognition navigation method, GPS (Global Positioning System) navigation method.

2. According to the drive mode: single drive, differential drive, dual drive, multi-wheel drive.

3. According to the transfer method: push-pull type, roller type, chain type, belt type, traction type, piggyback type, fork type, picking type, gantry type, robot type.

4. According to the communication method: wired communication, infrared light communication, radio communication, wireless local area network.

Through the operation of the intelligent system, the AGV axle vehicle can be separated from manual operation according to the established route, and can work 24 hours a day, which improves the efficiency of operation and greatly increases the stability of operation.For modern enterprises, this change is imperative.

AGV automated warehousing and handling equipment has been seamlessly integrated with MES, ERP, WCS, etc., realizing fully flexible and highly automated modern logistics, which can improve enterprise management to achieve modularization, intelligence and simplicity, and elevate factory automation to a new height.

SUNTECH Textile Machinery is committed to providing customers with innovated products such as motorized beam trolley that connecting with AGV technology, and excellent service, which is a professional worldwide enterprise with decades of experience and research. SUNTECH offers experienced experts timely and effective integrated services in pre-sales consultation, sales, maintenance, and comprehensive after-sales support, doing utmost to give the ultimate and comprehensive service experience.