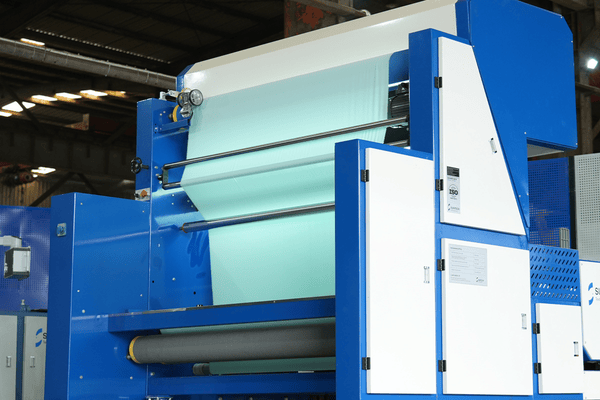

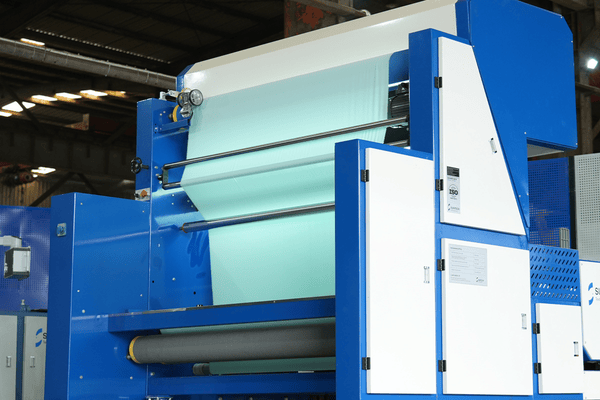

In the textile industry, fabric quality inspection has always been an important part of ensuring product qualification rate and improving customer satisfaction. As the limitations of manual fabric inspection efficiency and accuracy gradually emerge, the AI fabric inspection machine has come into being. It uses industrial-grade high-definition cameras combined with deep learning algorithms to achieve high-speed, accurate, and all-weather automated inspection, greatly improving the level of intelligence in textile production. Different types of textiles have different requirements for fabric inspection machines. Let's take a systematic look at the actual application of AI fabric inspection machines in various types of textiles.

Knitted Fabrics

Knitted fabrics such as cotton knitted fabrics, spandex knitted fabrics, ribbed fabrics, etc., are characterized by soft structure, good elasticity, and fine texture. When inspecting knitted fabrics, the AI fabric inspection machine must have:

Ultra-high-resolution camera to capture tiny defects such as broken threads, holes, and skipped stitches.

A sensitive image processing algorithm to identify subtle weaving defects in dense textures.

A flexible tension control system to prevent fabrics from stretching and deforming during the inspection process to ensure the authenticity of defect detection.

In actual applications, the AI fabric inspection machine can maintain a defect recognition rate of more than 95% under high-speed cloth rolling, greatly reducing missed inspections due to human negligence.

Woven Fabrics

Woven fabrics such as poplin, Oxford, canvas, and twill have regular weaving structures, but they are also prone to:

Uneven yarn thickness

Broken warp and weft

Jumping and wrong flowers

For these typical defects, the AI fabric inspection machine can not only detect common defects through the built-in million-level textile defect atlas database, combined with machine learning, but also automatically classify defect types and generate defect distribution maps to provide decision-making basis for subsequent process processing (such as repair and cutting). Especially for high-count and high-density woven fabrics, the performance of the AI fabric inspection machine far exceeds the stability of manual fabric inspection.

Elastic Fabrics

Elastic fabrics (such as four-way stretch and spandex blended fabrics) have large elasticity and are easily affected by tension changes during the inspection process. When the AI fabric inspection machine is applied to elastic fabrics, it is particularly necessary to:

Tension tracking system to adjust tension in real time to avoid stretching affecting the inspection effect.

Deformation compensation algorithm to ensure that defects can be accurately captured even if the fabric surface fluctuates.

In addition, some high-end AI cloth inspection machines also support real-time wide-width measurement, accurately record cloth width changes, and provide data support for subsequent shaping processes.

Printed Fabrics

Due to the variety of colors and complex patterns of printed fabrics, traditional manual cloth inspection is very likely to miss defects. When AI cloth inspection machines are applied to printed fabrics, they usually use:

Multi-spectral imaging technology to enhance the contrast of different color layers and improve the accuracy of defect recognition.

Pattern recognition algorithm to distinguish the design itself from real defects (such as missing prints, color differences, color bleeding, etc.).

Intelligent learning function, adaptive training for different printed patterns, the more you use it, the more accurate it is.

Especially in the field of high-end printing (such as digital printing and paint printing), AI cloth inspection machines can greatly improve the consistency and aesthetics of finished products and reduce the rework rate.

Home Textile Fabrics

Home textile fabrics (such as bed sheets, curtain fabrics, and sofa fabrics) are generally large in width and diverse in texture, which puts higher requirements on cloth inspection machines. The advantages of AI cloth inspection machines in the field of home textiles are reflected in:

Wide-width detection system (more than 2.2 meters), covering the entire fabric at one time.

High-speed roll inspection capability meets the continuous inspection needs of large batches of long rolls of fabric.

Defect marking and automatic classification facilitate subsequent cutting to avoid defective areas and improve material utilization.

Some high-end home textile brands have extremely high requirements for fabric appearance. With the help of AI cloth inspection machines, they can not only control the defect rate but also systematically manage the quality data of each batch of fabrics to create a high-quality supply chain system.

Functional Fabrics

Functional fabrics such as waterproof, fireproof, antibacterial, and UV-resistant fabrics usually have special coatings or fibers added. Traditional cloth inspection methods are difficult to detect hidden defects such as coating shedding, local density abnormalities, and functional layer breaks. AI cloth inspection machines can:

Combine infrared detection, ultraviolet imaging, and other technologies to assist in identifying problems that are difficult to detect with the naked eye.

Through deep learning models, the recognition accuracy of functional defects is continuously optimized.

This is of great significance for high-standard industries (such as military clothing and medical textiles).

Conclusion

From knitting to weaving, from elastic fabrics to functional fabrics, AI fabric inspection machines are fully empowering the quality management system of the textile industry with their high efficiency, precision,n and intelligence. It not only improves inspection efficiency and reduces labor costs, but also provides strong support for enterprises' quality traceability, production optimization, and customer satisfaction through big data analysis. In the future, with the continuous advancement of technology, AI fabric inspection machines will show greater potential in more subdivided fields, helping textile enterprises move towards a new era of intelligent manufacturing.