The textile industry is one of the most important and ancient industries in the world, providing clothing and household goods to people all over the globe. In recent years, the industry has undergone a transformation with the introduction of fabric relaxing machines. These machines have revolutionized the way fabric is treated and finished, making the process faster, more efficient, and more consistent. In this blog, we'll take a closer look at what fabric relaxing machines are, how they work, and the benefits they offer to the textile industry.

What is a Fabric Relaxing Machine?

A fabric relaxing machine is a machine that is used to remove tensions and wrinkles from fabric. It works by subjecting the fabric to a series of mechanical treatments, such as steaming, dampening, and stretching, that help to relax the fibers and remove any unwanted creases. The machine is designed to be highly automated, allowing for consistent and uniform treatment of the fabric.

How Does a Fabric Relaxing Machine Work?

The working of a fabric relaxing machine is simple yet highly effective. The fabric is loaded onto the machine, which then uses a combination of heat, steam, and mechanical stretching to remove any tensions and wrinkles. The heat and steam help to soften the fibers, making them easier to stretch and manipulate. The mechanical stretching then pulls the fabric in different directions, evenly distributing the fibers and removing any unwanted creases.

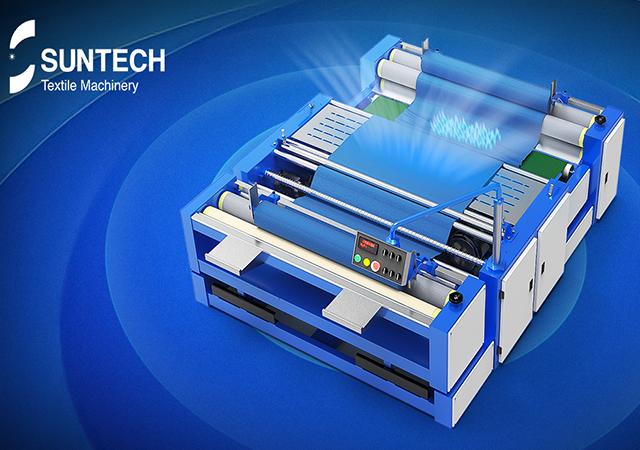

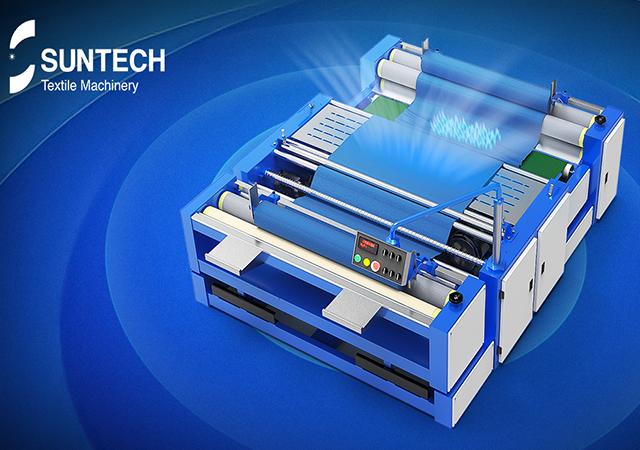

SUNTECH Fabric Relaxing Machine ST-FRM-VI(P)

The main purpose of manufacturing ST-FRM-VI(P) is the time-wasted work of free the fabric roll tension, and ST-FRM-VI(P) is mainly used to eliminate knit fabrics’ tension and to keep fabrics tidy for storage.

SUNTECH fabric relaxing machine is the best solution for unwinding and relaxing your fabric rolls because its consistent tension release and the perfect fabric rolls generation, which performs better than the traditional way from roll to plaited fabric relaxation.

ST-FRM-VI(P) has a special device that using for air floating, the tension control system also ensure a full relaxation of fabric in the shape of roll to roll, which can reduce out-of tolerance cut parts.

Features of ST-FRM-VI(P)

1. Tension-less fabric feed-positive surface unwinding from 2 rollers which are driven by separate motor and inverter.

2. Fabric passes over air-flotation zone for totally relaxing, to reduce processing time.

3. The vibrating conveyor release fabric tensions by shaking.

4. The output fabric roll, can be put onto the automatic spreading machine, save time and space.

5. Automatic Edge-alignment System, edge alignment error<6mm

6. Accurate Length Counting(Y/M)-counting error ≤0.1m/km

7. Automatic Width Measuring Device-- can be installed on machine for online measuring (option)

8. Automatic Weight Device--measuring capacity 1000-2000kgs

Benefits of Using a Fabric Relaxing Machine

There are several benefits to using a fabric relaxing machine in the textile industry.

1. Increased Efficiency

Fabric relaxing machines are highly automated, allowing for faster and more efficient processing of the fabric. This means that more fabric can be treated in less time, leading to increased productivity and cost savings for the textile industry.

2. Consistent Results

Because the process is automated, the results are consistent and uniform, ensuring that the fabric is treated in the same way every time. This leads to a more uniform final product and reduces the need for manual intervention.

3. Improved Quality

By removing tensions and wrinkles from the fabric, the final product is of a higher quality and has a more professional look. This can help to increase customer satisfaction and boost sales for the textile industry.

4. Lower Costs

Fabric relaxing machines are designed to be energy efficient, meaning that they use less energy than other methods of relaxing fabric. This leads to lower operating costs and increased profitability for the textile industry.

Conclusion

In conclusion, fabric relaxing machines are a revolutionary addition to the textile industry. They offer a fast, efficient, and consistent way to remove tensions and wrinkles from fabric, leading to improved quality, increased efficiency, and lower costs. If you are in the textile industry, consider investing in a fabric relaxing machine and see the benefits for yourself!