Introduction

In traditional weaving workshops, handling has always been a heavy and challenging task. Especially for heavy warp beams, the traditional manual handling method is inefficient and has safety hazards. With the continuous development of intelligent and automated technologies, electric warp beam transporters have become an important part of the intelligent upgrade of weaving workshops. It optimizes the production process of the workshop through advanced technical means, improves efficiency, and reduces labor costs, becoming a powerful assistant in the modern textile industry.

Transportation in the weaving workshop

Traditional workshop handling methods usually rely on manual labor or simple mechanical equipment. These methods have many problems, such as low efficiency, high labor intensity for workers, and dangerous operations. With the advancement of technology, intelligent handling systems have gradually entered weaving workshops. Intelligent handling systems can replace heavy manual operations improve the accuracy and speed of object handling and reduce the probability of accidents.

The electric warp beam transporter is atypical representative of intelligent handling. Due to its high efficiency, precision, and energy savings, have been widely used in modern weaving workshops. It can easily realize large-load handling, intelligent scheduling, and automated operation, improving the operating efficiency of the entire production line.

Advantages of Electric Warp Beam Trolley

Easy to Operate

The design of the electric warp beam cart allows one operator to complete the entire handling process independently. No matter how heavy, the electric warp beam cart can complete it efficiently, greatly reducing the dependence on manual labor.

Efficient Energy Saving, Reducing Costs

The electric warp beam cart has an efficient energy management system that can reduce energy consumption while ensuring handling efficiency. Reducing manual handling, can also effectively reduce labor costs and improve overall production efficiency.

Precise Control

The electric warp beam cart can accurately adjust the speed, position, and load through an advanced control system to ensure the safety of the operation process. In addition, its intelligent design can automatically identify environmental changes to avoid operating errors, to improve the safety of the working environment

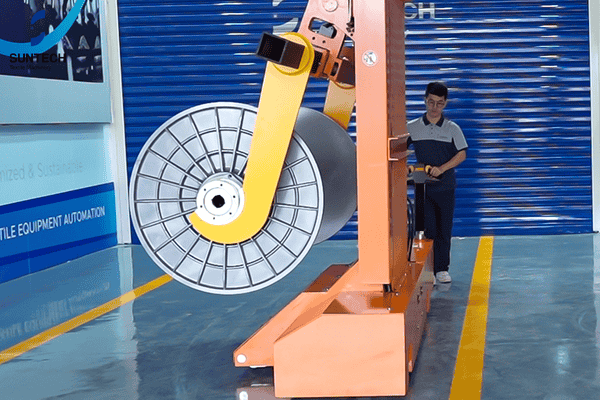

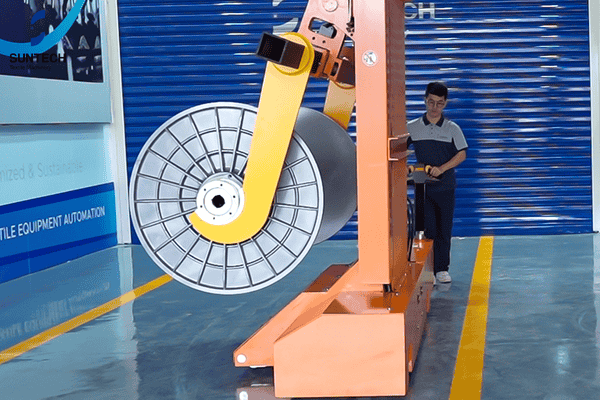

SUNTECH Electric Warp Beam Trolley

The core technologies of the electric warp beam trolley include a step-less speed regulation system, EPS steering system, and compact design. These technologies enable the electric warp beam trolley to operate efficiently in complex workshop environments, improving the flexibility and accuracy of operation.

Stepless speed regulation system: The electric warp beam trolley adopts stepless speed regulation technology so that the speed can be flexibly adjusted according to actual needs. Whether it is light load or heavy load, the operator can achieve smooth and stable operation, reducing the loss caused by improper operation.

EPS steering system: The EPS system allows the electric warp beam trolley to achieve precise steering, and it can be easily operated even in a small space, avoiding the inconvenience of traditional mechanical steering.

Compact design and high load capacity: The electric warp beam trolley has a compact design and can operate flexibly in a space-constrained environment. At the same time, it has a high load capacity and is suitable for use in large weaving workshops.

Electric Warp Beam Trolley Customer Case

A large weaving factory in Argentina chose an electric warp beam trolley as a handling tool when upgrading its workshop to intelligentization. After a period of use, the overall handling efficiency of the factory area has increased by more than 30%, and the downtime of the production line has been significantly reduced. Because the electric warp beam car has a high load capacity and a precise control system, it also helps the workshop save a lot of space and improves the layout optimization of the production line.

Development of Electric Warp Beam Trolleys

With the continuous improvement of the textile industry's demand for intelligence and automation, the electric warp beam trolley has become one of the core equipment of the smart workshop. It not only plays a role in efficient handling during the production process but also promotes the overall intelligent upgrade of the workshop. Through linkage with other intelligent devices, the electric warp beam trolley can realize the automatic scheduling, transportation, and distribution of materials, further improving production efficiency and the level of workshop intelligence.

In the future, the electric warp beam trolley will combine more advanced technologies, such as artificial intelligence (AI) and AGV technology, to become more intelligent and multifunctional. It can help the electric warp beam trolley make autonomous decisions, optimize handling routes, predict equipment failures, and realize real-time monitoring and remote control of equipment status. With the advancement of technology, the application scenarios of electric warp beam trolleys will be more extensive, and future weaving workshops will be more intelligent, efficient, and safe.

Conclusion

As important equipment for intelligent handling, electric warp beam trolleys are gradually becoming the core force for the intelligent upgrade of weaving workshops. With its high efficiency, energy saving, and precision, it improves production efficiency, reduces labor costs, and provides guarantees for the safe operation of workshops. With the continuous advancement of technology, electric warp beam trolleys will play a more important role in future weaving workshops and promote the entire industry to develop in the direction of intelligence and automation.