The transportation of textile materials is the most laborious and time-consuming step in the entire textile production process, and it is also the most critical step. It plays a role in production continuity, production efficiency, product quality, production flexibility, inventory cost, and production environment. It can be said that it runs through the entire production cycle of textiles.

At present, the most common problems encountered by textile factories are high costs, long transportation time, limited load-bearing capacity, easy damage during transportation, environmental pollution, and other problems. Follow us to explore the latest solutions.

Advantages of electric transportation equipment

High degree of automation: Electric transportation trolleys Electric Warp Beam High Lift Trucks and other equipment have a high degree of automation, which can reduce manual operations, improve production efficiency, and reduce labor intensity.

Precise positioning: These equipment are usually equipped with precise positioning systems, which can achieve fast and accurate material transportation, reduce error rates, and improve production efficiency.

Continuous operation: Electric equipment has a long endurance, can achieve long-term continuous operation, reduce downtime, and improve production efficiency.

Save labor costs: Automated equipment can replace a large number of manual labor and reduce labor costs.

Reduce noise: Electric equipment has low noise, which can improve the working environment and improve the working comfort of employees.

Flexible configuration: The equipment can be flexibly configured according to different production line layouts and material characteristics to adapt to different production scenarios.

How to Choose Suitable Transportation Equipment?

Types And Characteristics Of Textile Material Transportation Equipment

Electric Transport Trolley

Characteristics of Electric Transport Trolley

It uses electric drive, has a small body, and flexible steering, and is suitable for operations in narrow spaces. Strong carrying capacity: Different load models can be selected according to different needs to meet various transportation needs. Simple operation, humanized design, easy operation, and easy to use.

Function of Electric Transport Trolley:

It is used to transport mechanical parts, various raw materials, semi-finished products, and finished products in textile factories to improve work efficiency. Replace manual handling, reduce the labor intensity of workers, and improve production efficiency.

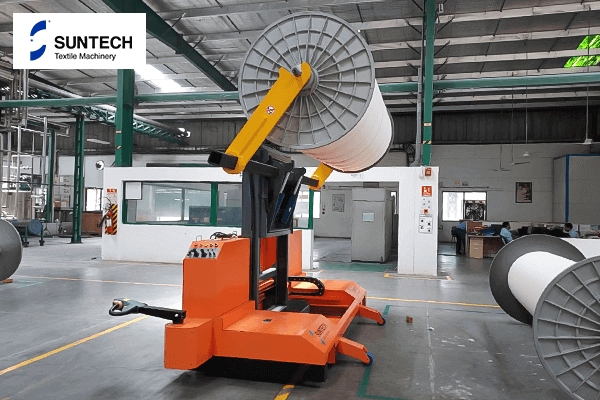

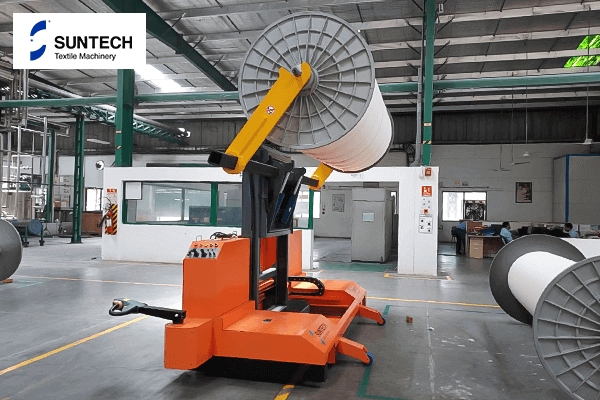

Characteristics of Electric Warp Beam High Lift Truck:

It is specially designed for the characteristics of the upper and lower axles in the textile industry and is easy to operate. Equipped with a lifting device, it can easily complete the lifting and lowering operations of the weaving shaft. The stable structure and strong carrying capacity ensure the safety and reliability of the axle process.

Function of Electric Warp Beam High Lift Truck:

Save manpower, replace manual axle loading, reduce labor intensity, and reduce labor costs. Improve production efficiency: shorten the axle loading time and improve the utilization rate of the loom.

Purchase Guide

Production demand analysis:

Material type, weight, size, transportation distance, frequency, production environment

Equipment performance indicators:

Load capacity, speed, battery life, charging time, safety performance

Brand and quality:

Brand awareness, market reputation, quality certification, after-sales service

Price and budget:

Price range of various equipment, how to choose the right equipment according to the budget

SUNTECH's Material Handling Equipment

We currently mainly provide Warp Beam Trolleys, Fabric Roll/Batch Trolleys, A-Frame Tractors, Material Handling Equipment, etc. Aim to offer a powerful combination of safety and efficiency. These robust machines are designed to effortlessly transport heavy warp beams, streamlining workflow and minimizing the risk of accidents.

Advanced safety features like emergency stop mechanisms and load limitations further enhance workplace security, protecting both operators and valuable materials.

Beyond safety, these trucks optimize efficiency. Their ability to handle bulk shipments minimizes downtime and accelerates production. The adjustable beam loading system and versatile harness mounting, with electronic UP&DOWN and stretching capabilities, provide unparalleled flexibility for diverse loading requirements.

Conclusion

As important auxiliary equipment in the textile industry, electric transport trolleys, and Electric Warp Beam High Lift Trucks play an important role in improving production efficiency, reducing labor intensity, and improving the working environment. They not only have the advantages of environmental protection, high efficiency, and easy operation but also can adapt to different production needs, providing strong support for textile enterprises to achieve automated and intelligent production.

SUNTECH has developed a variety of equipment for different needs, including manual, semi-automatic, automatic, and other categories to meet your diverse needs. You can send your specific information to sales@strength-group.com to obtain exclusive services.