In the textile industry, quality has always been the core on which enterprises rely for survival and development. Consumers are demanding higher softness, dimensional stability, and wearing performance of fabrics. Behind these qualities lies a crucial piece of equipment — the fabric relaxing machine. Especially in the fabric finishing stage, the fabric relaxing machine plays a decisive role and is an essential guarantee for the production of high-quality fabrics.

So, what exactly does a fabric relaxing machine do? Compared with traditional methods, how can it help textile enterprises stand out in the fierce market competition? This article will comprehensively analyze its advantages from multiple perspectives.

What Is a Fabric Relaxing Machine?

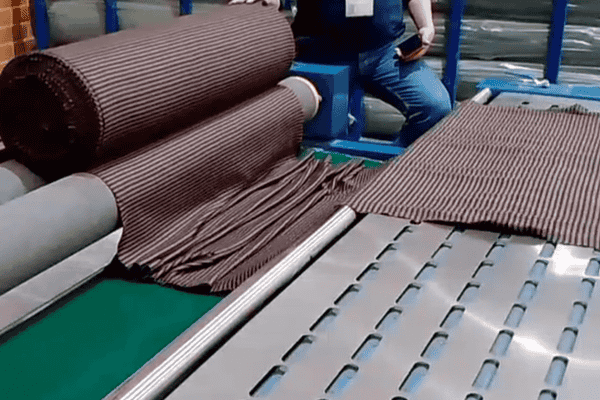

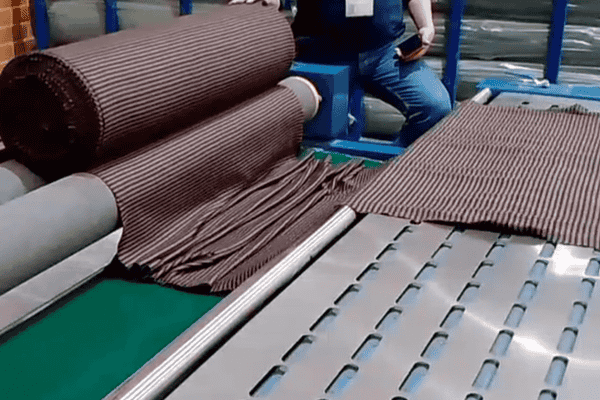

A fabric relaxing machine, also known as a fabric loosening machine, is a specialized device used to release internal tension within fabrics. Through a specialized conveying system and relaxing process, it allows fabrics — which have undergone prior processing such as setting, dyeing and finishing, or compression — to naturally recover under low or zero tension. This helps achieve dimensional stability, shrinkage prevention, and improved hand feel.

It is especially crucial when dealing with high-elasticity fabrics such as spandex-blended textiles, functional sportswear fabrics, and knitted fabrics.

The Origin and Hazards of Fabric Tension

Throughout the textile production process, from weaving to dyeing and then setting, fabrics accumulate a large amount of residual tension due to repeated mechanical stress. This tension may come from:

- Tension and stretching caused by high-speed rolling;

- Structural distortion from temperature changes during drying and setting;

- Fiber stress deformation due to physical compression during finishing.

If not promptly released, such tension can cause the following problems:

- Obvious shrinkage or deformation after washing;

- Hard surface and loss of elasticity;

- Dimensional instability during cutting, affecting garment quality;

- Higher return rates and damage to brand reputation.

Therefore, tension elimination is a necessary step to improve fabric quality — this is where the fabric relaxing machine comes in.

Key Advantages of Fabric Relaxing Machines

Triple Relaxing Process: Layer-by-Layer Tension Release

High-quality relaxing machines often adopt a three-stage relaxing system, including:

- Flat Conveying: Lays the fabric flat to reduce wrinkles;

- Swing Drop: Simulates natural falling to avoid sudden stretching;

- Tension-Free Stacking: Uses gravity to allow fabrics to rest naturally, fully releasing fiber stress.

This continuous process minimizes re-stretching during stacking and conveying, allowing the fabric to return to its "free form" under natural conditions.

Improved Hand Feel and Thickness

After the relaxing process, the fabric surface becomes fluffier and the fiber arrangement more natural, resulting in a noticeable softness and comfort. At the same time, the previously compressed thickness caused by tension is restored, enhancing both the visual and tactile experience and increasing the overall added value of the fabric.

Dimensional Stability and Shrinkage Control

Shrinkage control has always been a challenge for high-stretch and knitted fabrics. A relaxing machine can complete the pre-shrinking process before final finishing, significantly reducing end-product complaints due to shrinkage after washing and meeting the high quality consistency required by international clients.

Reduced Costs in Subsequent Processes

Fabrics treated by a relaxing machine exhibit better stability and manageability, which can significantly reduce cutting losses, improve sewing efficiency, and lower rework rates — ultimately saving considerable production costs for enterprises.

Wide Range of Applications, Especially for High-Stretch Fabrics

With the growing popularity of functional garments, sportswear, and intimate wear, high-stretch fabrics are taking a larger market share. These fabrics are more likely to accumulate tension during processing and have higher quality standards. As a result, they demand stricter relaxing treatment.

Fabric relaxing machines show excellent adaptability to these materials. They can automatically adjust based on fabric thickness, width, and elasticity, and even integrate with cutting systems — serving multiple functions with one machine and improving overall production line efficiency.

Trend Toward Intelligence

In recent years, as the textile industry shifts toward digitalization and automation, fabric relaxing machines have also been evolving with more intelligent features, such as:

- Automatic Tension Detection: Real-time monitoring of fabric condition and dynamic adjustment of conveying speed;

- Data Logging & Traceability: Stores relaxing parameters for each batch to aid in quality control;

- Touchscreen HMI: Intuitive interface supporting remote control and preset switching;

- Automatic Length & Weight Measurement: Aids in statistics and improves efficiency.

These features have turned the once "supporting" relaxing process into a critical step in the production chain, helping enterprises control quality and boost efficiency.

Conclusion

In today’s textile era that values high quality, differentiation, and intelligence, fabric relaxing machines are no longer optional accessories. Instead, they are powerful tools for enhancing fabric quality, optimizing production, and building enterprise competitiveness.

Whether you're dealing with conventional knitted fabrics or tackling the challenges of high-stretch materials, a fabric relaxing machine can provide precise control and intelligent tension release — helping businesses produce superior products and gain recognition from both customers and the market.