In textile manufacturing, efficiency and precision are paramount. Advanced fabric cutting machines have revolutionized how textiles are processed, offering significant benefits over traditional manual methods. This article provides insights into the advantages of these innovative systems, highlighting their impact on production speed, accuracy, waste reduction, and versatility. To delve deeper into the world of fabric cutting machines and explore the different types available, we invite you to read our comprehensive guide: The Ultimate Guide to Fabric Cutting Machines.

Increased Cutting Speeds and Efficiency

The evolution of automated cutting systems marks a significant leap in textile manufacturing, drastically boosting production rates. Innovations such as dual cutting heads and integrated labelers streamline the cutting process, reducing the time it takes to cut fabrics from minutes to mere seconds per piece. For instance, dual cutting heads can enhance cutting speeds by up to 40%, enabling synchronized and simultaneous cuts across different materials . Additionally, integrated labelers assist in sorting and tracking cut pieces, further minimizing human error and enhancing the flow of production.

These technological enhancements enable manufacturers to meet tight deadlines and rapidly changing market demands efficiently, ensuring that production never lags behind consumer expectations. By reducing cutting times, companies can significantly increase their throughput, facilitating a faster response to market trends and a more dynamic production cycle .

Enhanced Precision and Accuracy

Advanced fabric cutting machines leverage state-of-the-art technologies to ensure high precision and consistency, crucial for maintaining quality, especially in intricate designs. Laser-guided systems and CAD integration allow for exact cuts, drastically reducing discrepancies caused by human error. The precision of these machines is vital for complex patterns, where even minor deviations can lead to significant material waste or product defects.

Further innovations in pattern matching and fabric recognition systems enhance this precision. For instance, automated systems can now scan fabric prints and visually overlay patterns directly on the material before cutting, ensuring that each piece is perfectly aligned according to the design specifications. This technology not only improves the accuracy of cuts but also maximizes fabric utilization, significantly reducing waste .

Reduced Fabric Waste

Advanced fabric cutting technology significantly enhances the efficiency of material usage, drastically reducing waste. By employing sophisticated algorithms and CAD software, these systems optimize fabric layout and cutting paths, ensuring minimal waste. This optimization is crucial when using expensive materials like silk or leather, where reducing remnants is financially beneficial. For instance, certain high-tech cutting machines are engineered to reduce fabric waste by up to 20%, making a noticeable difference in cost savings for manufacturers .

The integration of smart technologies, such as automated nesting software, further enhances these capabilities. This software assesses various fabric patterns and dimensions, positioning them in a manner that maximizes the use of material. It's not just about cutting costs-this approach also aligns with sustainable manufacturing practices by decreasing the volume of textile waste that contributes to environmental pollution .

Versatility and Fabric Compatibility

Advanced fabric cutting machines offer unmatched versatility, equipped to handle a diverse array of textile materials, from the lightest silks to the heaviest denim. This flexibility is achieved through the use of modular tooling systems, which allow for rapid changes between cutting devices such as ultrasonic cutters for synthetics, laser cutters for precise work, and rotary blades for speed .

These systems adapt seamlessly to various fabric properties, ensuring optimal cutting performance without damaging the materials. Such versatility is essential in a production environment where multiple fabric types are processed daily, enabling manufacturers to switch between different production requirements without significant downtime.

Choosing the Right Fabric Cutting Machine for Your Needs

Selecting the ideal fabric cutting machine involves careful consideration of several crucial factors to ensure optimal efficiency and cost-effectiveness in your manufacturing processes:

Production Volume

Assess both your current and anticipated future production volumes. This evaluation will help determine the necessary capacity of the machine, ensuring that it can handle your production demands without bottlenecks. Machines designed for high-volume production offer faster cutting speeds and more durable components but may require a higher initial investment .

Types of Fabrics

Different cutting technologies excel with specific materials. For instance, laser cutters are ideal for precise cuts on delicate fabrics, whereas rotary blades might be better suited for quick trims on heavier materials. It's vital to choose a machine that can efficiently handle the range of fabrics you work with regularly, thereby optimizing both performance and fabric quality .

Complexity of Designs

Complex patterns and designs often require advanced features such as multi-layer cutting capabilities or intricate pattern matching. Selecting a machine with advanced technological integrations like CAD systems or laser-guidance ensures high fidelity in reproducing complex designs with minimal errors, which is crucial for maintaining design integrity and reducing waste .

Budget

Determine a budget that not only covers the initial purchase cost but also considers long-term operational costs, including maintenance, parts replacement, and energy consumption. Investing in a higher-end model might be more cost-effective over time due to lower maintenance costs and higher efficiency .

Implementation Strategies

Successfully integrating a new fabric cutting machine into your production line requires strategic planning and careful execution to minimize the disruption:

Seamless Integration

Develop a phased implementation plan that includes timelines for installation, testing, and full deployment. This approach helps mitigate risks associated with operational disruptions and allows for adjustments as needed without impacting the broader production processes .

Comprehensive Training

Providing thorough training for operators and maintenance personnel is essential. Well-trained staff can maximize the potential of the new equipment, reducing downtime and errors. Ensure that training covers both the operation of the machine and troubleshooting techniques to handle common issues .

Tailored Selection

Choosing a machine that aligns with your specific needs is critical. Consider all aspects, including the types of fabric you use, the typical complexity of your designs, and your production volume. This tailored approach ensures that the new machine will integrate smoothly into your existing operations and support your production goals effectively .

Optimizing Production with SUNTECH's Advanced Fabric Cutting Machine

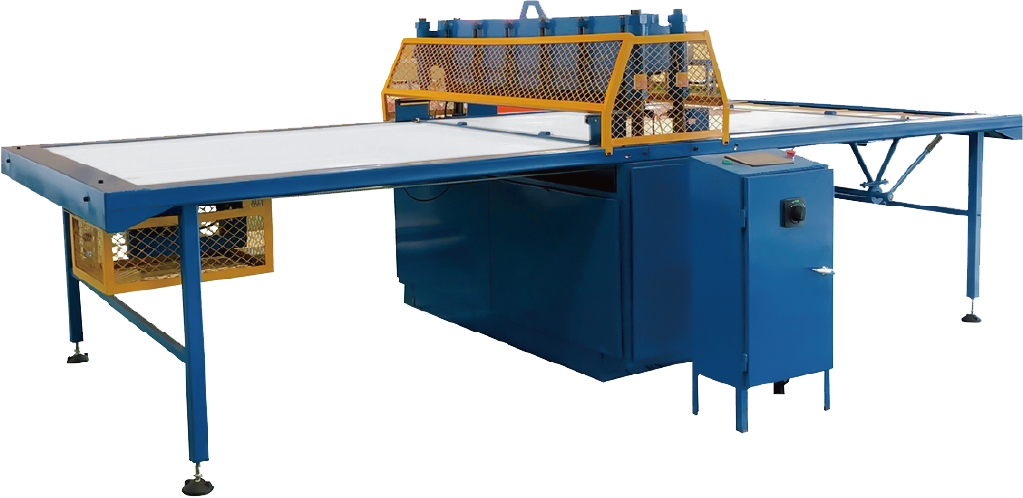

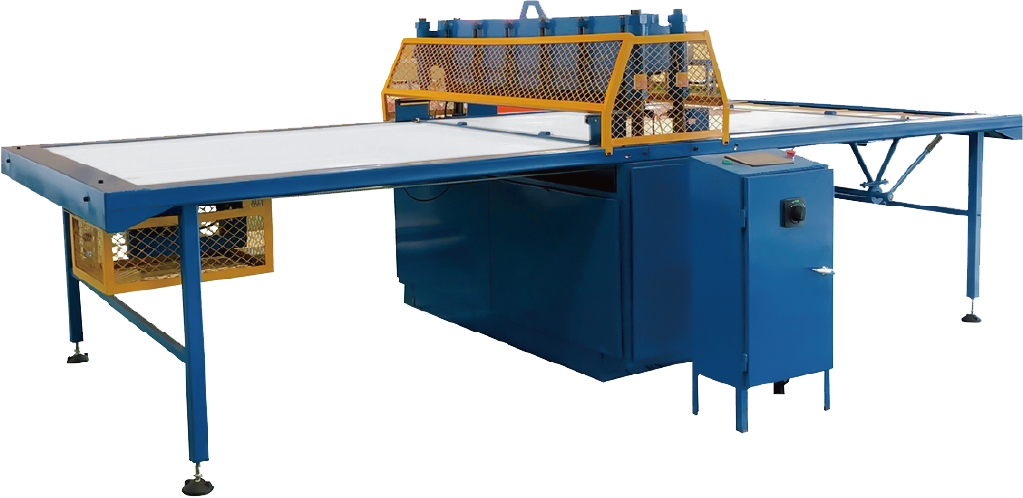

Incorporating a SUNTECH ST-USCM ultrasonic fabric cutting machine into your production line represents a strategic enhancement capable of meeting the high demands of modern textile manufacturing. This machine is designed to streamline operations while delivering unparalleled accuracy and efficiency.

✧ Precision and Versatility: The SUNTECH ST-USCM is engineered to cut with a precision of±5mm and is versatile enough to handle a variety of fabric types, from delicate silks to robust denims. With its advanced ultrasonic cutting technology, this machine ensures clean cuts without fraying or other damage, making it ideal for high-quality textile production.

✧ Efficiency and Speed: Capable of operating at speeds up to 30 meters per minute and accommodating fabric widths between 1.8 and 4.0 meters, the ST-USCM enhances throughput dramatically. This increased speed allows manufacturers to keep pace with market demands and reduces turnaround times significantly.

✧ Reduced Waste: The precision cutting technology minimizes fabric waste, which is crucial for cost control and sustainable manufacturing practices. By optimizing fabric usage, the ST-USCM not only cuts costs but also aligns with environmental standards by reducing waste output.

✧ Advanced Features: Equipped with features like full-width fabric inspection, synchronized operations, and various cutting modes (ultrasonic, laser, heat, and dry cutting), this machine is adaptable to any production need. The customization options available ensure that it can be tailored to specific operational requirements, adding an extra layer of operational efficiency.

Next Steps

If you're looking to enhance your textile production's efficiency, precision, and adaptability, consider the SUNTECH ST-USCM ultrasonic fabric cutting machine. With its advanced features and customization options, it is an ideal solution that meets the rigorous demands of modern textile manufacturing.

Contact us today to learn more about how the SUNTECH ST-USCM can transform your production capabilities and help you achieve a competitive edge in the marketplace. Don't miss the opportunity to take your production to the next level-reach out now for a consultation and see the difference advanced technology can make in your operations.