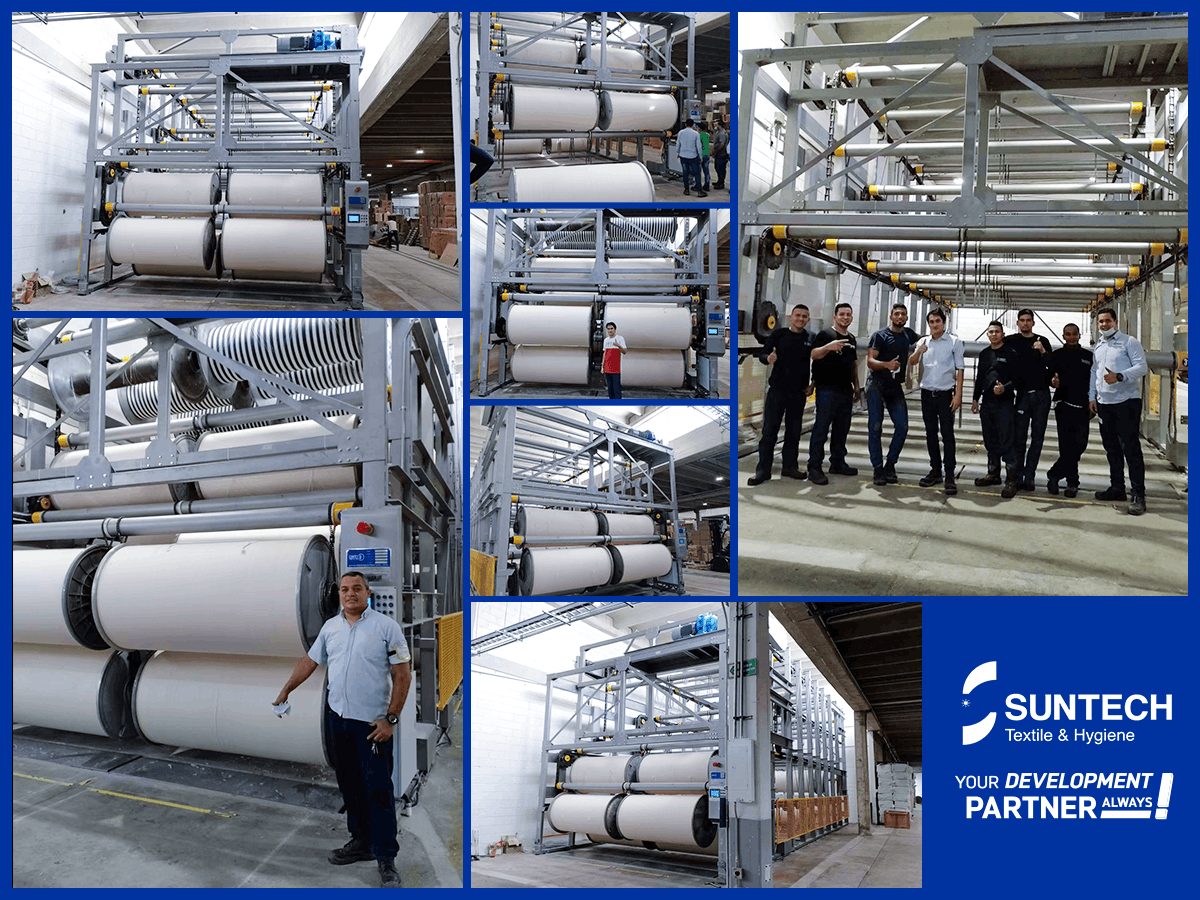

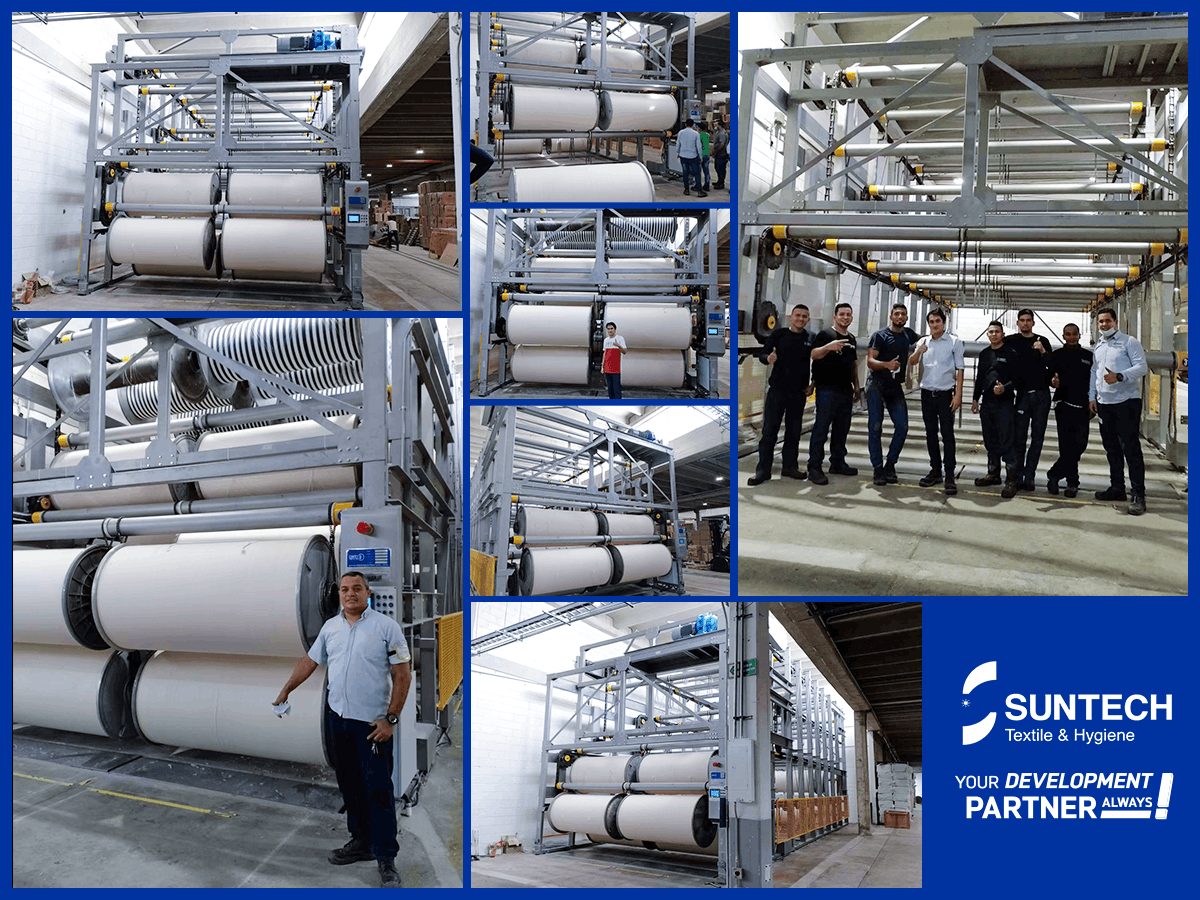

SUNTECH Intelligent Beam stacker, using carefully selected materials from top brands, incorporating advanced Beam Stacker design technology, refined through 50 years of technical expertise and functional optimization. With over 10,000 customers and 50,000 machine installation cases worldwide, SUNTECH has earned high praise from customers for its outstanding quality assurance and attentive after-sales service (including overseas technical support and a 12-month warranty), resulting in high customer retention rate. Currently, due to the partial shutdown of textile enterprises in India, textile orders from many countries have surged, leading to increased demand for SUNTECH "Beam stacker" to address textile warehousing issues. Customers who wish to purchase beam stacker are advised to inquire promptly, as we will provide customized solutions based on their requirements.

Over a decade ago, SUNTECH gained overseas recognition with its "Beam Storage" system, becoming one of the few manufacturers of Beam Storage at that time, and also ignited a technological revolution in the field of textile machinery. After years of technological innovation, today's SUNTECH Beam Storage system is even more intelligent and user-friendly.

7 Guarantee of SUNTECH Beam Stacker

Raw Material Guarantee--Sourcing From International Standard Steel

Giants

1.Guide Rail: According to different beam weight, we will choose different steel. Such as as 15kg Light Rail,which used in light rail construction. It is belongs to high-strength low-alloy weathering steel with a small thermal expansion coefficient

2.Beam Loading Shaft:Seamless Steel Tube

Seamless Steel is corrosion-resistant, especially the corrosion of acid, alkali, salt and atmospheric environment. It is high temperature resistance, and with good impact and fatigue resistance.Free of maintenance, Effective service life up to 15 years.

Seamless Steel’s tensile strength is 8-10 times more than ordinary steel.

Pillar: Purchased from International Standard Steel Giants with high strength

Chain:Heavy-duty transportation chain, suitable for high-intensity transportation.

Precision Guarantee--Components Processed by High-precision CNC,like Running Wheels, Chain wheels ,etc

CNC machining advantage:

1)Stable quality, High accuracy

2)Work Piece online inspection: real-time inspection of work pieces during machining,

detecting and correcting problems and errors timely.

Machining Guarantee----- CNC Cutting and Welding Qualified with Crack Testing Report

1)Advantages of CNC cutting: High efficiency,high quality and high precision,

2)crack detection,can provide test report.

Crack detection,which can use the sound,light,magnetism and electricity of material,to detect if there is defects, inhomogeneity on the testing object,and can also report the size,place and number of the defects.This detection won't damage and influence the performance of the testing object.

Detecting the internal defects can improve the products from following ways:

A.Improves manufacturing processes

B.Lower manufacturing cost

C.Improve the reliability of product

D.Ensure the safe operation of equipment

Artistic Appearance---Patented Shot Blasting Technology Improve the Fatigue Strength, Increase the Coverage; Optimize Surface Roughness.

Shot blasting technology can improve fatigue fracture resistance of material/parts, Prevent Fatigue Failure ,Improve Fatigue Life

Double Rustproof Guarantee--Epoxy primer+Surface metallic Painting

1.Epoxy primer

Epoxy prime is an anticorrosive coating with epoxy resin as the main film-forming material.It is used as primer,suitable for Carbon steel, cast iron and other iron materials,which has the functions of anti-corrosion, anti rust and salt fog resistance.

2.Surface metallic Painting:

The characteristics of metallic Painting is rich color,layering, rust proof,strong adhesion, high hardness, not easy to be scratched, oxidation and corrosion resistance.

Security

1.CE CERTIFICATE Comply with the health and safety requirements of Directive 2014/35/EU

The mechanical safety and electrical safety of our beam stacker comply with European CE standard.

3.The latest chain synchronization automatic detection technology, zero accident guarantee!

When the chains on both sides of beam stcaker are out of synchronous,beam stcaker will alarm and stop running,then operator can check whether bilateral chains need to adjust the degree of tightness.

4.Protection photo sensor: when beam stacker is running, if protection photo sensor detects that people or foreign body enter the running area, beam stacker will automatically alarm and stop.

Limit switch: to make sure there is a safe distance between beams and pillars,when beam stacker is running, if any beam touches pillar, beam stacker will automatically stop and alarm.

Safety guardrail: used for limiting and preventing specific activities within the scope of beam stacker.

The maximum rated loading capacity of beam loading shaft is one and half times the weight of beam weight.

Factory qualification guarantee: SGS approved,ISO9001:2008 Standard

Electrical configuration

1.France “SCHNEIDER”brand PLC

2.“SCHNEIDER”brand PLC with excellent operation ability, high-capacity memory,

easy maintenance, stable&reliable.

3.“WANNAN” brand gear motor.

No.1 brand of gear motor in China. small vibration, low noise, energy-efficient.

3. France “SCHNEIDER”brand touching screen

World famous brand, responding quickly and accurately.

4.“HRB”brand bearing.

HRB brand, one of three major brands in China bearing industry.

Intelligentization

1. Locating function, intelligently loading&unloading beam function.

Automatically locating beam position, automatically select the shortest path to doffing beam.

2.Searching function

Only need to input beam no.for automatically finding your required beam.

3.Multi-language selection

Standard language is English, it’s also available to customize language, easy operation!

4.Communicating function

Connection with ERP system, to realize data synchronization and sharing.

5.Barcode Reader

Scanning barcode on beam, intelligent identification-automatically reading and input system, no need manual input.

6.Software customization

Softwear can be customized as your specific requirements.

7. Mobile software controlling is available.

SUNTECH Textile Machinery Business has been dedicated to the development, production, and distribution of top-quality textile machinery since its establishment. With a focus on meeting the needs of global customers, all of our textile machinery has been exported outside of China. Our portfolio of textile machinery includes 2 main categories: STelego and fabric make-up machines series. Through years of technological expertise, we have earned high acclaim from customers worldwide for the exceptional reliability and productivity of our products. Notably, our flagship ST-BS(Beam Stacker) commands a leading market share in the industry.