Fabric relaxing machines play a pivotal role in the ever-evolving textile industry. These machines are essential in the textile manufacturing process, ensuring that fabrics are relaxed and ready for subsequent treatments or garment production. As the industry pushes towards greater efficiency, quality, and sustainability, understanding the latest technological trends in fabric relaxing machines is crucial for manufacturers aiming to stay competitive.

This article sheds light on the advancements in fabric relaxing technology, exploring how these innovations are transforming production processes and enhancing product quality.

Overview of Traditional Fabric Relaxing Machines

Traditional fabric relaxing machines have long been a staple in textile manufacturing. Their primary function is to remove the stresses and wrinkles from fabrics, making them smoother and easier to handle. These machines typically operate by feeding the fabric through a series of rollers and tension devices, which help to evenly distribute tension across the material. The process is crucial for ensuring that the fabric's final dimensions and properties are consistent and meet quality standards.

Despite their essential role, traditional fabric relaxing machines have several limitations. One major challenge is their inability to adapt to different fabric types and weights efficiently. Many older models lack the automation needed to handle variations in fabric tension and thickness, leading to inconsistent results. Additionally, these machines often consume a significant amount of energy and require extensive manual intervention, which can slow down production and increase operational costs.

Recent Technological Advancements

1. Automation and Smart Technology

The integration of automation and smart technology marks a significant leap forward in fabric relaxing machines. Automation has streamlined many processes, reducing the need for manual labor and minimizing human error. Modern machines now feature advanced control systems that can adjust tension settings, speed, and temperature based on real-time data. Moreover, the incorporation of IoT (Internet of Things) technology allows for remote monitoring and control, enhancing operational efficiency and enabling predictive maintenance. These advancements ensure that fabric relaxing machines are not only more efficient but also more reliable and easier to manage.

2. Enhanced Precision and Consistency

Achieving greater precision and consistency in fabric relaxation processes has been a major focus of recent innovations. Advanced sensors and digital controls have been developed to monitor fabric tension, width, and temperature with exceptional accuracy. Technologies such as automated width monitoring and synchronized length and width measurement ensure that fabrics are relaxed evenly, reducing defects and waste. These innovations are particularly beneficial for handling delicate fabrics and ensuring that the final product meets stringent quality standards.

3. Energy Efficiency and Sustainability

Sustainability is becoming increasingly important in the textile industry, and fabric relaxing machines are no exception. New technologies have been developed to reduce energy consumption and minimize environmental impact. For instance, many modern machines feature energy-efficient motors, heat recovery systems, and advanced insulation materials. Additionally, the use of eco-friendly lubricants and cooling systems helps to reduce the carbon footprint of fabric relaxing processes. These advancements not only contribute to sustainability but also help manufacturers reduce operational costs.

Advanced Features in Modern Fabric Relaxing Machines

1. Roll-to-Roll Processing

One of the key innovations in modern fabric relaxing machines is the roll-to-roll processing method. This technique maintains consistent tension throughout the fabric, reducing the need for reworking and enhancing production efficiency. By eliminating the risk of fabric distortion and ensuring uniform tension, roll-to-roll processing significantly improves the quality and consistency of the final product.

2. Steam Relaxing Machines

Steam relaxing machines have gained popularity for their effectiveness in preshrinking fabrics, particularly those made from elastomeric and Lycra materials. These machines use steam to relax the fabric fibers, making them easier to handle and process. Combining fabric re-inspection and relaxing functions in one machine, steam relaxing systems ensure a reliable and uniform relaxing effect. This technology meets high European standards, making it a preferred choice for many textile manufacturers.

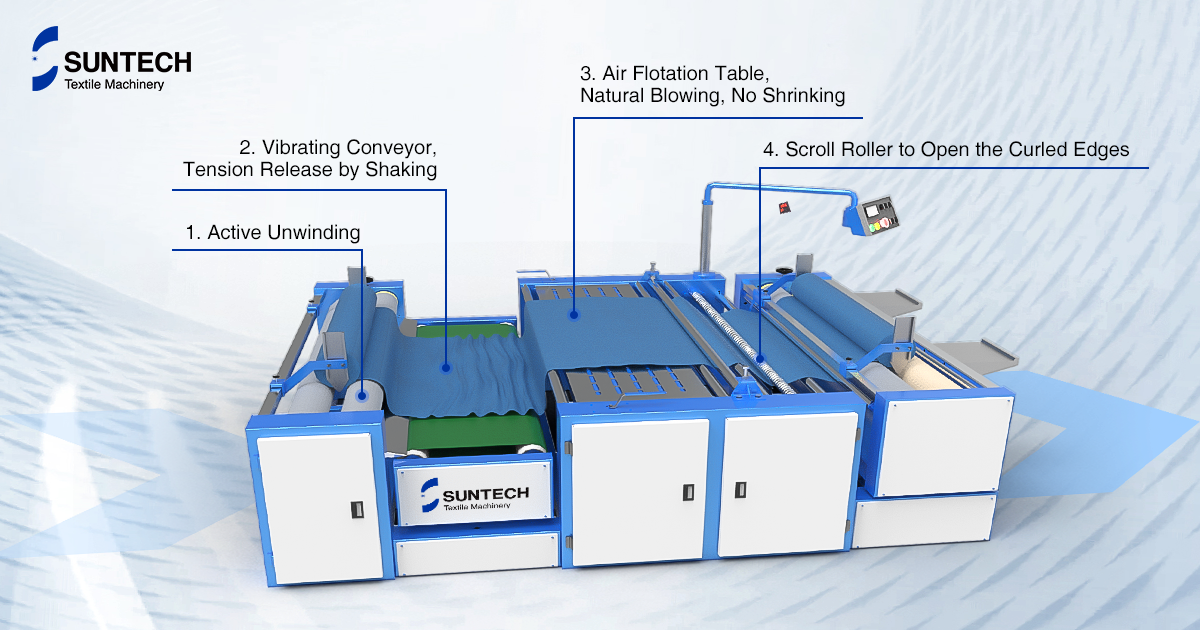

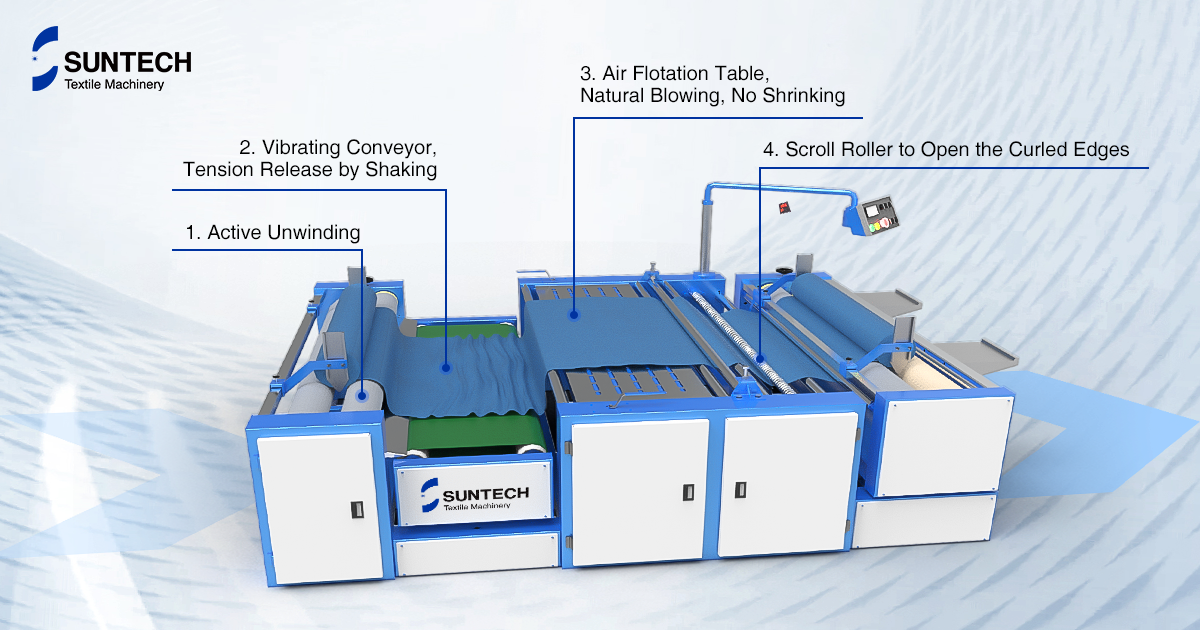

3. Advanced Measurement and Control

Modern fabric relaxing machines are equipped with sophisticated measurement and control systems. Features such as automatic width monitoring, synchronized length and width measurement, and digital output measuring wheels enhance precision and efficiency. For example, the SUNTECH Air Type Roll to Roll Fabric Relaxing Machine offers synchronized measurements and 100% tension release, ensuring no shrinkage and direct usability in cutting operations. These advanced features optimize marker making and cutting processes, reducing waste and improving productivity.

4. Increased Speed and Capacity

New models of fabric relaxing machines are designed to operate at higher speeds while handling larger fabric rolls. These machines offer customizable options to meet specific processing needs, making them more versatile and adaptable to various production environments. The increased speed and capacity of modern machines not only enhance productivity but also reduce production times, enabling manufacturers to meet growing market demands more efficiently.

Case Studies and Real-world Applications

FM Denim, a leading manufacturer of denim products, has significantly benefited from partnering with SUNTECH since 2017. Known for its extensive textile production capabilities, FM Denim has a global distribution network for its high-quality products. However, the company faced challenges with the inefficiency of repetitive processes in its production line. The need for automated machinery to reduce manual labor and streamline these tasks was critical.

In 2017, FM Denim required a machine capable of converting fabric rolls from the loom into plaited fabric for the wet processing phase. The existing process, involving fabric rolls with hollow pipes threaded through a shaft and placed on an A-frame, was inefficient and prone to fabric damage. SUNTECH provided a tailored solution with an advanced fabric relaxing machine, addressing these issues effectively.

The advanced technology and precision engineering of SUNTECH's machinery have enabled FM Denim to achieve higher production rates and improved product quality. This efficiency boost has been crucial in meeting the growing global demand for their denim products. The streamlined processes and reduced manual labor have not only enhanced productivity but also ensured consistent product quality, reinforcing FM Denim's position in the global market.

Future Trends and Predictions

As we look to the future, several trends are expected to shape the development of fabric relaxing machines:

1. Artificial Intelligence and Machine Learning: The integration of AI and machine learning technologies is set to revolutionize fabric relaxing machines by enhancing their predictive capabilities. These advancements will allow the machines to learn from historical data, enabling real-time process optimization and increasing operational efficiency. For example, AI could be used to predict and automatically adjust machine settings for different fabric types, minimizing the risk of errors and improving overall production quality.

2. Advanced Materials and Nanotechnology: Innovations in materials science, particularly nanotechnology, are expected to lead to the creation of more durable and efficient fabric relaxing systems. For instance, nanotechnology could be employed to develop new types of fabrics that are easier to relax without damage or to enhance the machine components themselves, making them more resistant to wear and capable of performing at higher efficiency.

3. Hybrid and Multi-Functional Machines: The trend towards hybrid and multi-functional machines is likely to continue, with new models integrating various textile processing operations into a single system. This could include combining dyeing, relaxing, and finishing processes, thereby streamlining production lines and reducing the need for multiple separate machines. Such integration not only saves space and cost but also reduces the time needed for textile processing.

4. Enhanced Connectivity and Industry 4.0 Integration: Future fabric relaxing machines will likely be equipped with advanced connectivity features, aligning with Industry 4.0 standards. This will facilitate better data exchange and integration with other manufacturing systems, allowing for more synchronized operations across different production stages. Enhanced connectivity will also enable remote monitoring and control of machines, providing manufacturers with the ability to quickly adapt to changes in production demands or process conditions.

These trends reflect a broader movement towards more intelligent, efficient, and integrated manufacturing solutions in the textile industry.

Conclusion

The technological enhancements in fabric relaxing machines are profoundly transforming the textile industry, elevating standards of efficiency, quality, and environmental responsibility. With the integration of automation, smart technologies, energy-efficient systems, and sophisticated measurement tools, modern fabric relaxing machines are redefining the landscape of textile manufacturing. As demonstrated by FM Denim, these advancements not only bolster productivity but also ensure that manufacturers can adeptly meet the increasing demands of the global market.

SUNTECH, a leader in textile machinery, epitomizes this progress with its innovative solutions that streamline and optimize fabric processing. The adoption of SUNTECH's advanced fabric relaxing machines by industry leaders highlights their pivotal role in the textile sector, promising enhanced fabric quality and operational efficiency.

Looking forward, the ongoing technological evolution is expected to bring even more significant improvements, solidifying the status of fabric relaxing machines as a foundational element of modern textile manufacturing. For those interested in leveraging these advancements, exploring SUNTECH's offerings can provide a direct pathway to integrating these state-of-the-art technologies into their operations.

To learn more about how SUNTECH's cutting-edge solutions can transform your fabric processing capabilities, visit SUNTECH today.

Read more: